Details of Sites and Operating Experience

| Sr No | Name of Client | Capacity | Type of client |

|---|---|---|---|

| 01 | Kalmeshwar Municipal Council, Nagpur | 2000 kg /day | Municipal Council |

| 02 | Katol Municipal Council, Dist. Nagpur | 2000 kg /day | Municipal Council |

| 03 | Indian Navy Colaba | 1000 kg /day | Indian Navy |

| 04 | Roha Municipal Council | 2000 kg /day | Municipal Council |

| 05 | Kalyan Dombivli Municipal Corporation | 2000 kg /day | Municipal Corporation |

| 06 | Hindalco Industries Taloja | 250 Kg /day | Industry |

| 07 | Ramtek Municipal Council, Dist Nagpur | 2000 kg /day | Municipal Council |

| 08 | Uran Municipal council, Raigad | 2000 kg /day | Municipal Council |

| 09 | Wardha Municipal Council, Nagpur | 2000 kg /day | Municipal Council |

| 10 | TCS Powai | 500 kg /day | Corporate |

| 11 | INS Trata Worli | 100 Kg/day | Indian Navy |

| 12 | TISS Deonar | 500 kg /day | Educational Institute |

| 13 | ACTREC Kharghar | 500 kg /day | Hospital |

| 14 | Satana Municipal Council Nasik | 2500 kg /day | Municipal Council |

| 15 | Vadodara Municipal Corporation | 5000 kg /day | Municipal Council |

| 16 | Goa Shipyard Limited Vasco Goa | 250 Kg /day | Central Govt. Institute |

| 17 | Indian Women’s Scientist Association | 50 kg /day | NGO |

| 18 | I I T Powai Mumbai | 2000 kg /day | Educational Institute |

| 19 | Trimbkeshwar Municipal Council Nasik | 2000 kg /day | Municipal Council |

| 20 | Deonar Abattoir BARC & MCGM | 15000 kg /day | Municipal Corporation |

| 21 | Kalyan Dombivli Municipal Corporation | 10000 kg /day | Municipal Corporation |

| 22 | Karjat Municipal Council Raigad | 5000 kg /day | Municipal Council |

| 23 | Mahad Municipal Council Raigad | 5000 kg /day | Municipal Council |

| 24 | TCS Andheri | 500 kg /day | Corporate |

| 25 | Hindustan Aeronautics Limited Nasik | 5000 kg /day | Central Govt. Institute |

| 26 | DCSEM DAE Mumbai | 3000 kg /day | Central Govt. Institute |

| Total | 75700 kg /day |

Project Photos

Location

Methodology Statement of Bio Gas Plant

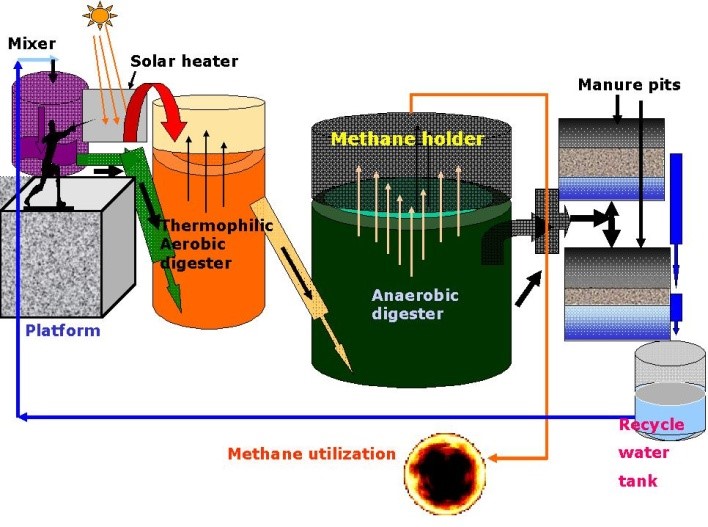

BARC has developed NISARGRUNA Bio Gas Technology for the treatment of organic waste. The bio gas plant works on principle of Biomethanation where thermophilic microorganisms treat the organic waste to generate methane gas and organic manure.

The biogas plant consists of following units.

- Mixer / Crusher: Segregated organic waste (frees of plastic, paper, metal, clothe and glass) is charged into mixer along with water. It is crushed here to obtain uniform slurry.

- Primary Digester: The organic waste slurry mixed with hot water is charged into primary digester. The primary digester serves mainly as hydrolysis cum acidification tank for treatment of suspended solids. Compressed air is used which helps in increasing aeration. The primary digester is designed in such a way that after the system reaches equilibrium in initial 4-5 days the fresh slurry entering the tank will displace the equal amount of digested matter from top into main digester tank.

- Main Digester: Main digester serves as methane fermentation tank and BOD reduction takes place here. The bio gas is collected in a dome (gas holder). It fits like a cap on the mouth of digester and it is submerged in the water. The bio gas produced from slurry is collected in dome and being lighter than air it rises upward. 1” / 2 “ MS /GI piping is provided to transfer the biogas.

- Sludge drying bed: The treated overflow of main digester is connected to sludge drying beds or manure pits. Natural drying of slurry results into high quality organic manure.

Schematic Layout and Process Flow Chart

Salient features of BARC NISARGRUNA TECHNOLOGY

- Technology developed by BARC

- Two stage Aerobic and Anaerobic process

- Air Circulation in Primary Digester.

- Methane Recirculation in Secondary Digester.

- Use of hot water and air Compressor.

- Easy to operate, no complex mechanism.

Advantages of Bio gas Plant

- A very convenient way to treat biodegradable waste.

- Clean, hygienic and pollution free environment.

- Airtight top covers of the system hence no odor or smell.

- No flies, mosquitoes or rats and rodents problem.

- Electric consumption and water consumption are very low.

- Saving on transportation of waste.

- Smoke free fuel can be used for cooking, in boilers or for electricity generation.

- Compact size and Organic manure as a by product

Gas Utilization System

- Gas can be used directly for cooking by installing special type of burners.

- For Hot Water Generation.

- Gas can be supplied to bio generator / micro turbine and Electricity can be generated to be used for street lights at surrounding areas. Diesel not required.

- Gas can be fed to boiler and steam can be generated. Dual burners can be developed which can run on gas and FO/ LDO.

List of Civil Equipment

- Primary Digester

- Main Digester

- Waste receiving and final segregation platform and shed

- Shed Above Primary Digesters for processing

- Slurry collection chambers

- Manure Pits

- Inlet and Outlet Chambers

List of Mechanical Equipment

- Mixer – 5/7.5 hP *2 No

- Compressor = 3 / 5 HP * 2No

- Gas Holder (Dome) = 4 mm MS sheet with FRP coating

- Gas Burner

- Gas Meter 16/20 M 3 /hr

- Air Grid – 1” GI Pipe Line C class in Primary

- Methane Recirculation grid – 1 “ GI Pipe Line in Main

- Gas Pipe line – 2 “ MS Line

- Water Pump – 2 HP

- Slurry Pump – 2 HP

- Weighing Balance-

- Solar Water Heating System -

- Moisture Separator – 2 “ MS Pipe “W “ shaped Structure

- Fire Extinguisher

- Water Tanks – 5000 lit & 1000 lit

List of Equipment for Power Generation

- Feed Blower – 2 HP

- Collection Blower – 2 HP

- Gas Balloon – 60 m 3

- H 2 S Scrubber

- Biogenerator-40 KVA - 3 Phase, Autocarburetion

- Chiller cum Moisture Separator

- Control Panel – 630A / 100 A

- Other Related Electrical Accessories